Safety, Reliability, and Peace of Mind: Hire Knowledgeable Hoist Inspectors Today!

Are you prioritizing the safety of your workers and the smooth operation of your lifting equipment? Look no further than DSM Hoist's team of knowledgeable hoist inspectors. With years of experience in the industry, our inspectors have the expertise and know-how to provide exceptional service that ensures maximum safety, reliability, and peace of mind for your manufacturing plant or Facility.

Why Choose DSM Hoist for Your Hoist Inspections?

1. Unparalleled Expertise

Our team of hoist inspectors consists of highly skilled and knowledgeable professionals who possess an in-depth understanding of hoists and their associated safety guidelines. With their comprehensive training and experience, they can effectively evaluate and identify potential issues, ensuring compliance with industry standards, government regulations, and best practices.

2. Thorough Inspections

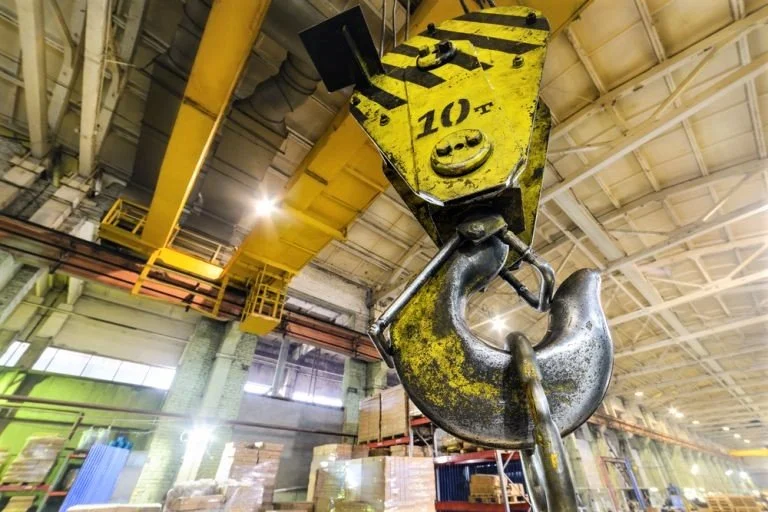

At DSM Hoist, we leave no stone unturned when it comes to hoist inspections. Our knowledgeable inspectors conduct meticulous assessments of your hoisting equipment, examining every component and performing critical tests to detect even the smallest signs of wear, damage, or malfunction. By addressing potential issues proactively, we prevent costly breakdowns and downtime, avoiding unnecessary disruptions to your operations.

3. Customized Solutions

We understand that every business, plant & facility has unique requirements. That is why our inspectors tailor their approach to suit your specific needs. Whether you require a one-time inspection, regular maintenance inspections, or specialized evaluations, we provide customized solutions that align with your budget, timeframe, and operational constraints. Our goal is to help you maintain the efficiency and safety of your overhead cranes & hoists while minimizing risk and maximizing productivity.

4. Compliance and Risk Mitigation

By engaging our DSM team, you demonstrate a commitment to compliance and risk mitigation. Our inspectors stay up-to-date with the latest regulations and best practices, ensuring your equipment meets all necessary safety standards. We meticulously document our findings and provide detailed reports that contribute to your compliance records and risk management strategies. Rest assured, with our inspections, you'll be well-prepared for any external audits or inspections.

5. Efficiency and Cost Savings

Investing in our knowledgeable hoist inspectors can save you both time and money in the long run. By identifying potential issues early on, we help you avoid expensive repairs, replacements, and operation disruptions. Our proactive approach enhances the lifespan and performance of your lifting equipment, maximizing your return on investment. Plus, with optimized safety and reduced downtime, you can maintain a productive work environment and increase your bottom line.

Contact DSM Hoist Today and Elevate Your Safety Standards!

Why compromise on safety when you can collaborate with a team who prioritizes your well-being and operational success? Contact DSM Hoist today to schedule an inspection or learn more about our comprehensive range of services. Together, we can ensure safety, reliability, and peace of mind for your lifting operations.